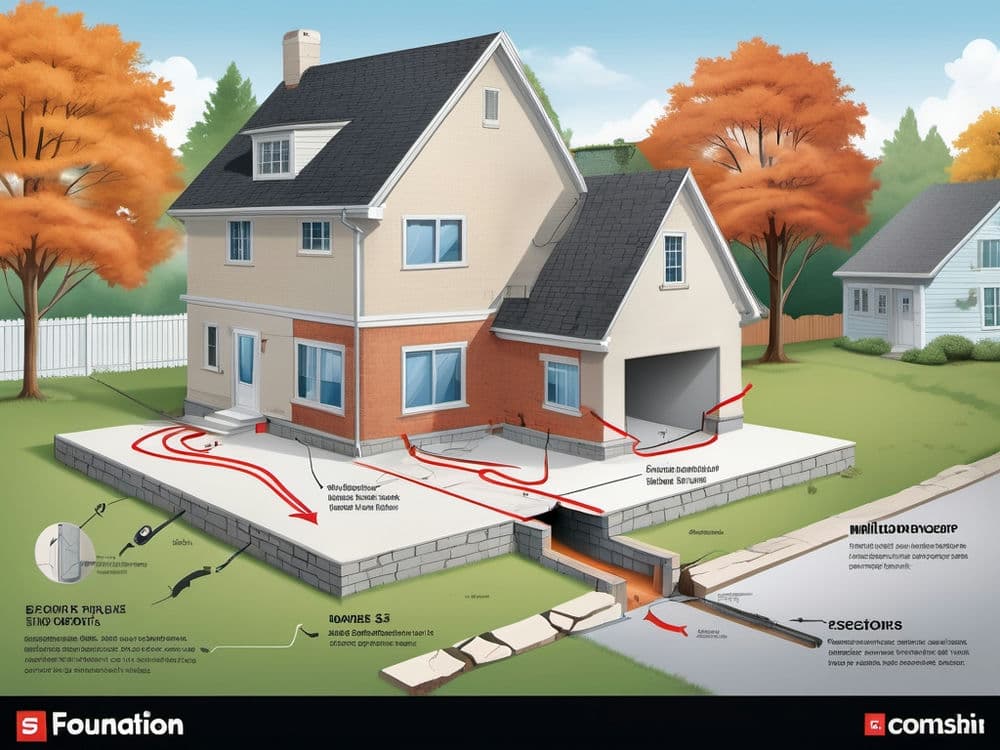

Helical pile installation marks an important change in foundation engineering, providing a cost-effective and efficient solution for commercial and residential structures. This technology, echoing the basic principles of geotechnical engineering, has transformed the method we use to approach foundation stability, especially in challenging soil conditions.

Helical piles' design integrates the physics of screw threads as well as the helix geometry, which makes them ideal for penetrating various soil kinds. The components, constructed from robust materials like steel, show incredible tensile strength as well as durability. Their unique design minimizes ground disturbance, a feature that is particularly useful in environmentally sensitive zones.

One of the main factors in helical pile construction is to achieve the required load capacity. This is when the relationship between installation torque and load capacity becomes essential. Contemporary torque indicator, such as those from Chance Digital Torque Indicator, play a pivotal role in this process, offering accurate measurements, and removing the uncertainty that are associated with the estimation of hydraulic pressure.

The operating speed during installation is vital, generally ranges between 8 and 16 RPMs. This controlled speed makes sure that the pile is moving about three inches each revolution in accordance with the helical plates' pitch. If the pile doesn't advance in the manner expected, adjustments such as increasing downward thrust or adding larger plates to prevent'spinning out' similar to a screw ripping its threads.

Flexibility With Prefabricated Foundations T&D World

Posted by on 2020-01-17

President's Awards Presented at DFI Annual Conference Tunneling Business Magazine

Posted by on 2019-11-08

'Our busiest year yet': Contractor says more residents installing screw piles to mitigate overland flooding CBC.ca

Posted by on 2019-07-26

Safety put 'in jeopardy' by some companies shoring up shaky homes, industry complaint alleges CBC.ca

Posted by on 2019-06-23

APA Solar Racking unveils new 3-rail racking system Solar Power World

Posted by on 2019-01-30

Helical piles help keep heavy equipment safely supported on large solar projects Solar Power World

Posted by on 2018-08-27

Avoiding the costly consequences of frost heave on solar ground-mounts Solar Power World

Posted by on 2018-03-05

Earth anchors—more than helical piles and ground screws—help make ground-mount solar more profitable Solar Power World

Posted by on 2017-08-14

The construction industry constantly seeks creative solutions to increase efficiency, reduce costs, and ensure the structural integrity. In this pursuit Helical piles have emerged as a revolutionary technology, changing the way we think about foundational support. This article delves into the causes behind the rising popularity of helical piles in construction, exploring their unique benefits and applications that are driving this transformation.

Helical piles, also referred to as screw piles, are deep foundation solutions used to anchor new or existing foundations. They are constructed of steel and feature an helical lead section which permits them to be driven into ground in the same way as a screw into wood. This design is a significant change from conventional concrete foundations and offers a variety of advantages that are suited to contemporary building requirements.

The world of construction is ever-evolving with new techniques and methods continuously evolving to meet the challenges of the 21st century.

Alongside their main advantages, helical piles have a variety of other advantages that make them more prominent in contemporary construction. These include:

These additional features, coupled with their main benefits are what create Helical piles extremely flexible and efficient foundation option for a wide range in construction tasks.

It is the most important attribute of the helical piles. They are adaptable to a wide range of soil kinds and conditions, making them a viable option for a wide range of projects, ranging from industrial structures to residential ones. Their design can be tailored to suit specific load requirements and can be used in various construction scenarios.

Helical piles also offer the advantage of immediate load bearing capacity. When they are installed, they can be able to support loads immediately and offer a distinct advantage over conventional methods that have to wait for concrete to cure. This feature is especially useful when projects have tight deadlines or in emergency situations where time is of the essence.

Finally, the environmental benefits of helical piles should not be neglected. They are often made from recycled steel. They are fully dismantleable, allowing reuse in future projects. This reusability, combined with their reduced carbon footprint during installation is in line with the increasing focus on sustainable construction practices.

In the end, the hidden strengths of helical pile installation - speed, minimal environmental impact, flexibility and immediate load capacity and sustainability - explain their increasing popularity in the construction field. While we seek the most efficient, cost-effective, and environmentally sustainable construction methods Helical piles are an effective, creative solution to today's construction challenges.

In addition to the strengths of helical piles, their use in construction projects offers many advantages. These can be outlined as follows:

These issues highlight the multiple benefits of making use of the helical piles and highlight their importance in enhancing efficiency, sustainability and efficiency in construction.